Electrical Hazard Analysis, focusing on the arc flash study process, is a proactive approach to electrical safety that goes beyond compliance. By arc flash study process experts assess and mitigate hazards in electrical systems through data-driven insights, guiding informed decisions on control measures like equipment modifications and improved maintenance. This ensures a safer work environment while adhering to arc flash safety standards and industry best practices, minimizing risks and potential injuries or fatalities associated with arc flash events.

Electrical hazards pose significant risks in industrial settings, making it crucial to implement robust control measures. This article delves into essential aspects of electrical safety, focusing on two critical components: Electrical Hazard Analysis and Arc Flash Study Process. Understanding these foundational steps is key to identifying potential risks and adhering to Arc Flash Safety Standards, ensuring a safer work environment. We’ll explore each process in detail, providing a comprehensive guide for professionals seeking to mitigate electrical hazards effectively.

- Understanding Electrical Hazard Analysis: The First Step in Ensuring Safety

- Arc Flash Study Process: Uncovering and Mitigating Potential Risks

- Adhering to Arc Flash Safety Standards: A Comprehensive Guide for Compliance

Understanding Electrical Hazard Analysis: The First Step in Ensuring Safety

Electrical Hazard Analysis is a critical process that forms the cornerstone of ensuring electrical safety in any work environment. It involves a comprehensive assessment and understanding of potential risks associated with electrical systems and equipment, specifically focusing on arc flash hazards. This analysis goes beyond mere compliance with arc flash safety standards; it’s about identifying vulnerabilities and implementing proactive measures to mitigate risks.

By conducting an arc flash study process, professionals can determine the potential risks associated with electrical gear, including the intensity of a possible arc flash and the corresponding personal protective equipment (PPE) requirements. This data-driven approach allows for informed decision-making, leading to the implementation of appropriate control measures. These might include modifying equipment design, enhancing maintenance practices, or establishing stringent safety protocols, ultimately fostering a safer work environment and aligning with industry best practices.

Arc Flash Study Process: Uncovering and Mitigating Potential Risks

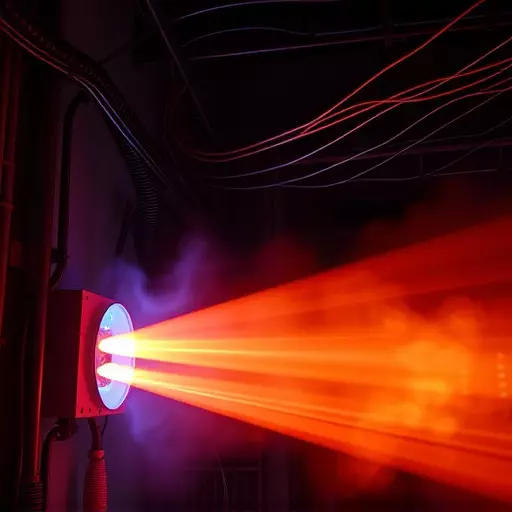

The arc flash study process is a systematic approach to identifying and mitigating potential risks associated with electrical hazards, specifically focusing on arc flash events. It involves a comprehensive analysis of an electrical system’s design, operation, and maintenance procedures to uncover any vulnerabilities that could lead to dangerous arcs forming and releasing explosive energy. This process adheres to stringent arc flash safety standards, which are critical for the well-being of workers and the preservation of equipment in industrial settings.

During the study, engineers meticulously evaluate each component within an electrical circuit, taking into account factors such as voltage, current, and potential faults. By simulating various scenarios, they can predict the likelihood and consequences of arc flash incidents. Once risks are identified, appropriate control measures are implemented, ensuring that personal protective equipment (PPE) guidelines are followed, and engineering solutions are designed to prevent or minimize the impact of such events.

Adhering to Arc Flash Safety Standards: A Comprehensive Guide for Compliance

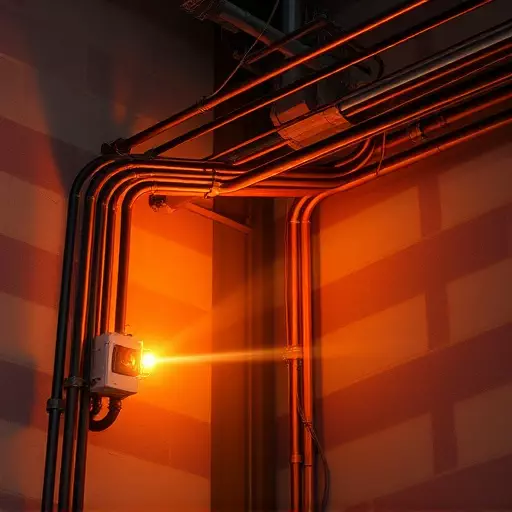

Adhering to Arc Flash Safety Standards is a comprehensive process that begins with a thorough understanding of the electrical systems in place. The first step involves conducting an extensive electrical hazard analysis, which identifies potential arc flash risks across all equipment and circuits. This includes assessing the voltage, current, and energy levels associated with each component. By thoroughly mapping out these hazards, organizations can identify areas where protective measures are necessary.

The arc flash study process delves deeper into specific scenarios, calculating incident energies and determining appropriate Personal Protective Equipment (PPE) requirements. It involves careful consideration of factors like distance, duration, and magnitude of an arcing event, guiding the selection of safety equipment such as insulated tools, clothing, and gloves. Compliance with Arc Flash Safety Standards ensures that employees are equipped to work safely around high-risk electrical situations, minimizing the potential for severe injuries or fatalities associated with arc flashes.