The arc flash study process, initiated by a rigorous Electrical Hazard Analysis (EHA), is key to mitigating electrical hazards. EHA involves scrutinizing every electrical component for potential arc flash risks, considering voltage, current, and fault currents. This data, coupled with safety measure reviews, guides the implementation of customized safety protocols adhering to arc flash safety standards. Accurate labeling on equipment, informed by this process, protects workers by communicating risk levels, protective gear requirements, and emergency procedures, fostering a culture of arc flash safety and reducing risks in industrial settings. Regular audits ensure these measures remain robust and aligned with industry best practices.

“In the realm of electrical safety, understanding arc flash labeling requirements is paramount for managing risks in industrial settings. This comprehensive guide delves into the intricate aspects of arc flash studies and their vital role in identifying electrical hazards. We explore the step-by-step process of uncovering these dangers, emphasizing the significance of electrical hazard analysis in mitigating risks. Furthermore, we provide an insightful overview of arc flash safety standards, ensuring worker protection and compliance with essential guidelines.”

- Understanding Arc Flash Labeling Requirements: A Comprehensive Overview

- The Arc Flash Study Process: Uncovering Electrical Hazards

- Electrical Hazard Analysis: Identifying and Mitigating Risks

- Adhering to Arc Flash Safety Standards: Ensuring Worker Protection

Understanding Arc Flash Labeling Requirements: A Comprehensive Overview

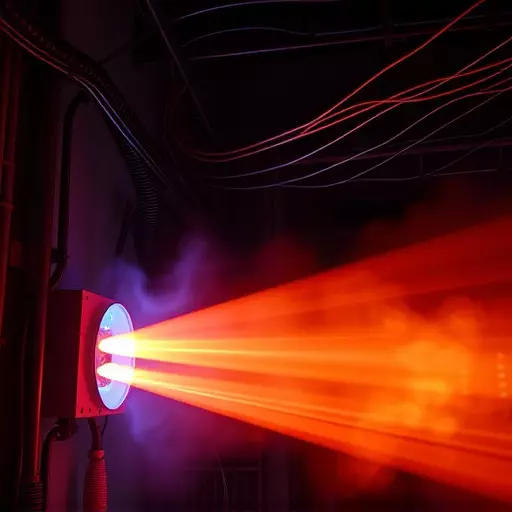

Understanding Arc Flash Labeling Requirements involves a meticulous arc flash study process that evaluates electrical systems and identifies potential hazards. This comprehensive analysis considers factors such as equipment design, energy levels, and human exposure to determine the likelihood and consequences of an arc flash event. The outcome informs the development of tailored safety measures aligned with arc flash safety standards, ensuring compliance with relevant regulations.

These labeling requirements are crucial for safeguarding workers who maintain or operate electrical systems. Clear, accurate labels on equipment provide critical information about potential risks, protective clothing necessary, and emergency response protocols. By adhering to these standards, organizations can foster a culture of arc flash safety, minimizing the risk of severe injuries or fatalities associated with these high-energy electrical events.

The Arc Flash Study Process: Uncovering Electrical Hazards

The Arc Flash Study Process begins with a thorough Electrical Hazard Analysis (EHA). This involves systematically evaluating every electrical panel, piece of equipment, and circuit within a facility to identify potential arc flash risks. During the EHA, qualified personnel consider factors such as voltage, current, power factor, and available fault currents to determine the energy that could be released in an arc event.

This initial analysis is followed by a detailed review of existing safety measures, equipment ratings, and protective device settings. By combining this data with the EHA results, professionals can identify areas where improvements or additional safeguards are necessary to ensure compliance with arc flash safety standards and protect personnel from electrical hazards.

Electrical Hazard Analysis: Identifying and Mitigating Risks

Electrical Hazard Analysis is a critical step in ensuring arc flash safety across industrial facilities. This process involves a comprehensive study of electrical systems, identifying potential risks and hazards associated with arc flashes. By meticulously examining equipment, circuits, and operational procedures, professionals can pinpoint areas vulnerable to these dangerous events. The analysis encompasses evaluating electrical components, understanding load currents, and assessing the proximity of personnel and sensitive equipment to potential arc flash sources.

Through this rigorous process, facility managers and safety officers can implement targeted mitigation strategies. This may include upgrading electrical systems, installing protective gear, improving training programs, and adhering to established arc flash safety standards. By integrating an in-depth understanding of electrical hazard analysis into their operations, organizations can significantly reduce the risks associated with arc flashes, fostering a safer working environment for all employees.

Adhering to Arc Flash Safety Standards: Ensuring Worker Protection

Adhering to Arc Flash Safety Standards is paramount in ensuring worker protection during electrical work. The process begins with a comprehensive arc flash study, which involves a detailed evaluation of electrical systems and potential hazards. This study goes beyond simple compliance; it identifies specific risks associated with each piece of equipment, leading to tailored safety solutions. By integrating the findings from an arc flash study into their daily practices, organizations can implement effective risk mitigation strategies.

These safety standards are not one-size-fits-all; they must be customized based on the unique characteristics of each workplace and job role. Regular audits and updates to electrical hazard analyses ensure that protection measures remain robust and aligned with evolving industry best practices. Through these diligent efforts, organizations can significantly reduce the risks associated with arc flash events, fostering a safer environment for all workers.